Current location: Home > Products > Petrochemical equipment series products

The Furnace Safety Monitoring System (FSSS) is an important measure toprevent accidents in heating furnaces or boilers caused by the accumulation offlammable materials and misoperation, and to ensure

+86 0730-8752158

The Furnace Safety Monitoring System (FSSS) is an important measure toprevent accidents in heating furnaces or boilers caused by the accumulation offlammable materials and misoperation, and to ensure the safe operation ofheating furnaces and boilers. The flame detection device is a key equipment ofFSSS, and the successful operation of FSSS largely depends on the correct andreliable operation of the flame detection device. The flame detection devicegenerally consists of a probe, a signal cable, and an operational amplifierprocessor.

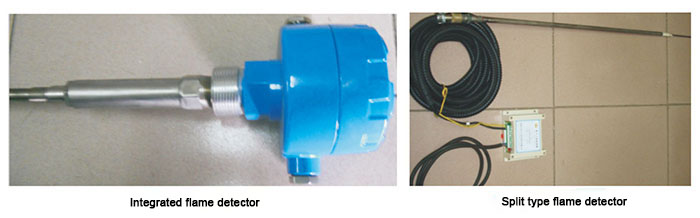

Ion flame detector

This product is suitable for detecting flame signals in variousindustrial furnaces. High temperature materials are selected, and the normaldetection temperature is between 800 ℃ and 1250 ℃. It is particularly widelyused in flame detection in industrial ceramic kilns, petrochemical, and steelheating furnaces. This series of ion flame detectors can be divided into two types:separated and integral. The separated type includes two parts: flame detectorand ion probe.

Main technical indicators of flame detectors

| Main technical indicators of integrated ion flame detector |

Main technical specifications of split type ion flame detector |

| 1. Power supply voltage 220V ± 10% 5/0/60Hz |

1. Power supply voltage 220V ± 10% 5/0/60Hz |

|

|

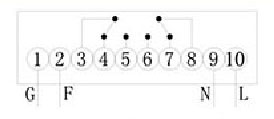

| Internal wiring instructions: G is the grounding terminal, connected to the outer shell of the lamp, F is the high-voltage terminal, connected to the flame detection probe, 3 and 8 are the common terminals of the relay, 4 and 7 are the normally closed terminals of the relay, and 5 and 6 are the normally open terminals of the relay |

Internal wiring instructions: G is the grounding terminal, connected to the outer shell of the lamp, F is the high-voltage terminal, connected to the flame detection probe, 3 and 8 are the common terminals of the relay, 4 and 7 are the normally closed terminals of the relay, and 5 and 6 are the normally open terminals of the relay |

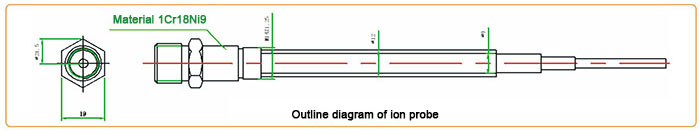

Main technical specifications of ion flame probes

1. Detection electrode: Pyrmax high-temperature alloy with a diameter of12 and a diameter of 4 extending into the fire zone.

2. The installation of the detection electrode must be able to come intocontact with flames, with a detection hole diameter of 12.5mm, and theelectrode's long-term working temperature of 1300 ℃, without the need forcooling.

3. Installation size: M18 × 1 or M18 × 1.5 threaded connection.

Infrared flame detector

The infrared flame detector is a new type of intelligent flame detectorwith communication function. It is a new product independently developed by ourcompany following the development trend of international flame detectionproducts and accumulating years of experience in production equipment andon-site debugging of flame detection equipment. It is suitable for detectingflame signals in burners primarily fueled by fuel and coal.

Main technical indicators of infrared flame detectors

| Integrated infrared flame detector |

Split type infrared flame detector |

| 1. Response wavelength: 850nm~1700nm |

1. Power supply voltage 220V ± 10% 5/0/60Hz |

| Temperature range: -40~75 ℃, humidity: 0%~95% non condensing; |

Temperature range: -40~75 ℃, humidity: 0%~95% non condensing; |

|

|

Internal wiring instructions: G is the grounding terminal, connected to the long lamp housing, F is the high voltage terminal, connected to the blue wire of the probe, 3 and 8 are the common terminals of the relay, 4 and 7 are the normally closed terminals of the relay, 5 and 6 are the normally open terminals of the relay, and 9 and 10 are the power input terminals. Ensure proper wiring before powering on. |

UV flame detector

The ultraviolet flame detector (UV) uses highly sensitive sensors toquickly detect most flame radiation within this spectral range. The product hasthe characteristic of resisting Japanese light interference and is mainly usedin hydrocarbon flames. The detection distance is 1 square foot and the gasolineflame is 500 feet. Provides standard outputs for flame and fault relays, aswell as optional 4-20mA analog outputs.

Technical specifications of ultraviolet flame detector

| Integrated UV flame detector |

Split type UV flame detector |

| 1. Response wavelength: 160-260nm |

1. Power supply voltage 220V ± 10% 5/0/60Hz |

| Temperature range: -40~75 ℃, humidity: 0%~95% non condensing, atmospheric pressure: 86KPa~108KPa, cooling airflow: 25.5Nmh |

|

|

|

Internal wiring instructions: G is the grounding terminal, connected to the long lamp housing, F is the high voltage terminal, connected to the blue wire of the probe, 3 and 8 are the common terminals of the relay, 4 and 7 are the normally closed terminals of the relay, 5 and 6 are the normally open terminals of the relay, and 9 and 10 are the power input terminals. Ensure proper wiring before powering on. |

Hunan Zhongding Thermal Technology Co., Ltd.

Address:No. 9 Changhu Road, Yueyang District, China (Hunan) Free Trade Zone.

Tel: +86 0730-8752158

Fax: +86 0730-8248020

Email: jacktang311@foxmail.com

Website: www.hnzdrg.com

Copyright © 2020-2024 Hunan Zhongding Thermal Technology Co., Ltd. All Rights Reserved.

湘ICP备19020679号