Current location: Home > Products > Petrochemical equipment series products

During theoperation of heat exchange equipment such as boilers and heating furnaces, theheating surfaces such as water-cooled walls, superheaters, economizers,preheaters, and flues are often plagued b

+86 0730-8752158

During theoperation of heat exchange equipment such as boilers and heating furnaces, theheating surfaces such as water-cooled walls, superheaters, economizers,preheaters, and flues are often plagued by surface ash and slagging, which havebeen a long-standing and difficult problem to solve in production. It not onlyweakens the heat transfer on the heating surface, resulting in low thermalefficiency of the system and reduced production load, but also may causeunexpected shutdown and significant economic losses when the heating surface isseverely dusty and slagging occurs.

Integratedfrequency conversion acoustic cleaning system

ZSB-1, ZSB-IItype acoustic soot blower

★The ZSB typesonic soot blower adopts precision rotary valve sonic sound generationtechnology and acoustic impedance matching sonic amplification transmissiontechnology, with a sound generation power of up to 2KW and an effective radiationradius of 7-10 meters. Compared with existing domestic and foreign sonic sootblowers, it has high sound power, high radiation sound pressure level, largeeffective radiation radius for soot blowing, and no dead corners for cleaning.

★ Easy maintenance:There are no components or vulnerable parts that extend into the furnace, movein or out, or rotate.

★ Low usagerequirements: There are no special requirements for compressed air, and thereis no need for purification, dehydration, or other treatments.

★ Easymaintenance: The automatic control device adopts PLC control operation, whichis easy to maintain and has a long service life, and can avoid dailymaintenance.

★ Low energyconsumption: The sonic soot blower uses compressed air, resulting in low energyconsumption.

★ Wideapplicability: It can remove surface ash from various types of boilers,passenger furnaces, heating furnaces (coal, oil, gas, slag, etc.),electrostatic precipitators, bag filters, cyclone dust collectors, ventilationand dust removal pipelines, fan volutes, blades, powder conveying pipelines,silos, hoppers, and separators.

★ Good sealingperformance: able to adapt to harsh environments below 65 ℃ and with high dustconcentration.

ZSB Type AcousticSoot Blower System

A PLC withmature application experience is used as the control host in the controlcabinet. The operation program of the soot blower is designed and stored in thePLC memory according to the process requirements (usually running in a singletimed sequence intermittently). On the basis of having certain hard operationmethods set on site, OP unit control technology is adopted. Whether manual orautomatic, its operation is completed by the PLC fixed program. The PLC has aMODBUS bus interface and can be configured and monitored for operation throughnetworking. The working program and operating parameters of the soot blower canalso be rearranged and set through the human-machine dialogue operation screen.

Product parameters of sound wave generator

|

Technical Parameter |

Model |

|

|

ZSB-1 |

ZSB-11 |

|

|

Adjustable

range of sound wave frequency (Hz) |

70-800 |

70-800 |

|

Sound pressure

level (dB) at a distance of 1 meter from the sound source |

≥145 |

≥145 |

|

Emission sound

power |

800-2000W

(adjustable) |

800-2000W

(adjustable) |

|

Effective

radiation radius |

4~7 |

4~7 |

|

Operating

ambient temperature (℃) |

-20~60 |

-20~60 |

|

Power supply

voltage |

three phase

380V 50Hz |

three phase

380V 50Hz |

|

Power supply

(KW per unit) |

0.75 |

1.2 |

|

Gas source

type |

compressed air |

compressed air |

|

Air source

pressure (MPa) |

0.4-1.0 |

0.4-1.0 |

|

Single unit

gas consumption (m/min) working condition |

≤2.5 |

≤2.5 |

|

Protection

level |

1P55 |

1P55 |

|

Explosion

proof level |

Design as

needed |

Design as

needed |

|

Characteristics

of Control Cabinet |

PLC

intelligent control, fixed operating parameters and methods |

PLC+HMI

intelligent control, operating parameters and methods can be set through the

human-machine window |

|

Installation

method |

Wall hanging

and platform outside the furnace |

Platform

outside the furnace |

Composition of ZSB type acoustic soot blower system

1. Ash cleaner (sound wavegenerator)

2. Sound duct

3. Control cabinet: ZSB-IItype with HMI (human-machine interface) ZSB-I type without HMI;

4. Main shut-off valve

5. Shut-off valve

6. Filter

7. Solenoid valve

Technical principle of ZSB type acoustic soot blower

The sonic soot blower refers to a method of using the energy of thesound field to remove ash from the heating area of the boiler, which iscompletely different from other ash cleaning technologies.

Sound wave soot blower technology is the process of convertingcompressed air or steam into high-power sound waves (a type of pressure wavethat propagates in the space medium (air) in the form of dense waves) andsending them into a furnace or a space that needs to be cleaned. When theaccumulated ash on the heating surface is repeatedly pulled and compressed byalternating density waves of a certain frequency, it will loosen and fall offdue to fatigue, be carried away by the airflow, or sink to the ash hopper fordischarge under the action of gravity.

Shock wave cleaning system

This product utilizes combustion pulses to achieve ash removal on theheating surface of the boiler, which is an efficient, energy-saving, andenvironmentally friendly soot blowing technology. Through the promotion and useon various boilers, this soot blowing method has successfully replaced thetraditional "steam wet blowing" with "shock wave pulse dryblowing", solving the problems of "steam wet blowing". Avoidingthe increase in flue gas humidity caused by wet blowing, greatly improving theefficiency of soot blowing, reducing pipeline corrosion rate, reducingmaintenance frequency, significantly reducing exhaust temperature and flue gasresistance, improving thermal efficiency, increasing unit output, reducingoperating costs, and solving the long-standing problem of long-term ashaccumulation and coking in boilers. Greatly improved the comprehensive economicbenefits of the enterprise.

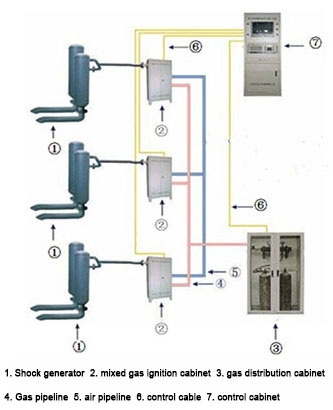

Composition of ZJB shock wave soot blower system

The ZJB shock wave soot blower system consists of a control section, agas supply control section, a gas distribution ignition section, a shock wavegenerator, and connecting pipelines (as shown in the figure below). The gassupply control section adopts advanced flow control technology, with preciseproportioning and low gas consumption. In particular, the shock wave generatorhas been innovated, improving the blowing intensity and safety reliability ofthe detonation shock wave on the boiler superheater, economizer, air preheater,and other heat exchange surfaces.

The structural diagram of the shock wave soot blower system is shown inthe figure.

Basic principle of shock wave soot blower

Basic principle: Shock wave soot blower, also known as weak blastwave soot blower, shock wave soot blower, pulse soot blower, etc. The ZJB shockwave blower uses combustible gases (such as coal gas, acetylene, natural gas,liquefied petroleum gas, etc.) to mix with air in a certain proportion toproduce characteristic gases. Based on high turbulence and adjustable pulsefrequency, it ignites the mixed gas and emits shock waves and strong soundwaves at the outlet of the shock wave tank. Its ash removal mechanism isreflected in the following three aspects:

Mechanical shock: The shock wave emitted by the nozzle usuallycarries pressure (1.0 MPa) and a high speed (1500 m/S), producing a similareffect to a steam soot blower (0.8 MPa~1.5 MPa), directly acting on the heatingsurface, causing the accumulated ash on the surface of the pipe to rupture anddetach from the attachment surface.

Sound wave radiation effect: When deflagration gas enters the furnace,it is often accompanied by a huge sound, and this sound wave is low-frequencyand not easy to attenuate. Through the tensile and compressive alternatingstress of the sound wave, the accumulated ash becomes loose and falls off.

The thermal cleaning effect of airflow: When the high-temperaturegas reaches the heated surface, the carried thermal energy softens the surfaceash of the pipe; Reduce the adhesion between the accumulated surface and theaccumulated ash, and achieve dust removal on each heat exchange surface underthe blowing of air flow.

Steam Soot Blower

There are two types of steam soot blowers: long telescopic soot blowersand electric fixed rotary soot blowers. They are used in industrial furnacessuch as petrochemical tube heating furnaces and boilers to clean the surface offurnace tubes or the accumulated ash deposits on the heating surface ofboilers, in order to improve the thermal efficiency of furnaces. Due to thelarge platform occupied by the equipment, the long retractable soot blower isnot compact enough, and the maintenance space requirements are large, so it isno longer widely used. The electric fixed rotary soot blower can use steam orcompressed air as the blowing medium. The number, diameter, and arrangement ofthe soot blowing gun barrel and nozzle, as well as the blowing arc, aredesigned according to the specific situation of the heating surface. Based onthe analysis data of coal and ash, smoke temperature, and blowing medium,recommend operating parameters (blowing pressure). During operation, when thereis a change in the type of coal or fuel, and the ash deposition situationchanges, the blowing pressure or the number of cycles (1 or 2 cycles) for eachblowing can be adjusted to improve the blowing effect.

Characteristics of steam soot blower

1. Can perform effective blowing work within the range of 3600, 2700,240 °, 1800, and 1200;

2. After the first and second rounds of blowing, changing the stopposition of the blowing pipe by 1800 can reduce or even eliminate the bendingdeformation of the blowing pipe caused by high temperature in the furnace,which is beneficial for the normal operation of the equipment and prolongs itsservice life;

3. Using contactless switches instead of traditional travel switches toreduce maintenance frequency;

4. Adopting two structural forms of eccentric shaft or eccentric wheelto ensure valve opening and closing, in order to facilitate normal soot blowingeach time;

5. Simple structure, small size, light weight, easy installation, andlow maintenance workload.

Main technical parameters of steam soot blower

| Soot blowing pipe speed |

1.5r/min |

Motor |

Type |

JW6324,YBS0-7114(explosion proof) |

| Blowing radius |

1.0~2.5m |

Power |

N=250W |

|

| Blowing angle |

3600、2700、2400、1800、1200 |

Speed |

m=1400r/min |

|

| Purging working fluid |

Steam or compressed air |

Harmonic Drive |

Type |

XB3-80-160 |

| Working fluid pressure |

1.0~2.0MPa |

Speed ratio |

i=160 |

|

| Working fluid temperature |

≤3200C |

Output torque |

100N.m |

|

| Total speed ratio |

1=933.33 |

Rated input speed |

N=3000r/min |

|

| Control mode |

Contactless switch (one set) |

Equipment weight |

60kg |

|

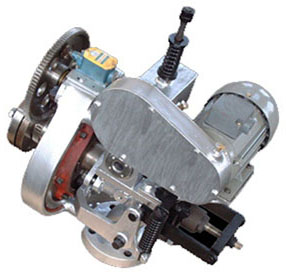

Working principle of steam soot blower

The soot blower is powered by an electric motor, which drives a harmonicreducer and a pair of gears to form a reduction mechanism, driving the sootblowing pipe connected to the hollow gear shaft to rotate. At the same time, italso drives the gear installed on the eccentric shaft (or shaft) to rotate. Dueto the eccentricity relationship of the eccentric shaft (or eccentric wheel),the single row centripetal ball bearing (or eccentric wheel installed on theshaft) installed at the end of the eccentric shaft also generates eccentricity,and the valve body is pressed according to a certain angle relationship to openthe valve stem channel. The blowing medium enters the soot blowing pipe with aspray hole through the hollow gear shaft and sprays out the accumulated ashdeposits on the surface of the furnace tube. Every time the eccentric shaft oreccentric wheel rotates one circle, By using a set of contactless switches, themotor is stopped from rotating (at this point, the soot blowing pipe hasalready rotated one and a half circles), the valve stem is reset with the helpof a spring, and the valve body channel is closed, completing a soot blowingprocess. When blowing again, restart the motor and repeat the above steps.Complete another blowing, and after each blowing, the stop position of theblowing pipe changes 180 °. The soot blower can achieve control of multipleprograms.

Hunan Zhongding Thermal Technology Co., Ltd.

Address:No. 9 Changhu Road, Yueyang District, China (Hunan) Free Trade Zone.

Tel: +86 0730-8752158

Fax: +86 0730-8248020

Email: jacktang311@foxmail.com

Website: www.hnzdrg.com

Copyright © 2020-2024 Hunan Zhongding Thermal Technology Co., Ltd. All Rights Reserved.

湘ICP备19020679号